Oerlikon is a leading global innovator in surface technology, polymer processing and additive manufacturing. Its solutions and comprehensive services, complemented by advanced materials, improve and optimize the performance, function, design and sustainability of customers' products and manufacturing processes in key industries.

The Balzers site develops and produces coating systems and thin-film coatings that significantly improve the performance and service life of precision components and tools for metal and plastics processing.

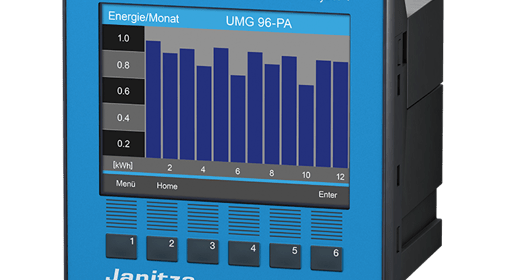

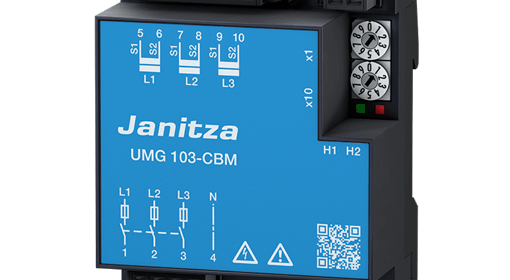

The increase in energy costs has also presented Oerlikon with a new challenge. In order to be able to take effective countermeasures, it is important to draw up a precise energy balance sheet. This is the only way to determine where and how much energy is being consumed. This transparency is essential in order to be able to take targeted measures to reduce consumption.

Another important factor for Oerlikon is the transparency of energy costs. The company wants to know how much energy is consumed in the various buildings and departments in order to distribute the costs accordingly. It makes sense to calculate the energy costs per cost center in order to enable accurate billing for accounting purposes.

Water consumption should not be ignored either. Precise monitoring and control of water consumption can also contribute to energy efficiency and reduce costs.