How can you prevent this?

Business interruptions and property damage caused by fire can jeopardize a company's existence. Preventive fire protection is therefore a key issue within corporate safety.

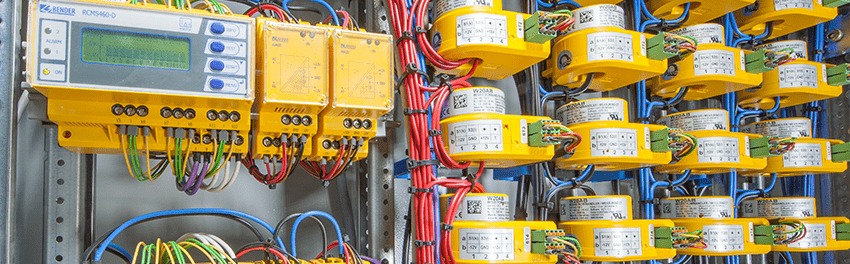

The best way to prevent a fire hazard in the electrical installation is to constantly monitor the residual currents of all important systems (parts) and devices. For this purpose, residual current monitoring devices or systems are installed in addition to the existing protective devices.

What does permanent residual current monitoring with RCM technology from Bender mean?

- Potential fire hazards caused by high fault currents are detected as soon as they arise

- Preventive safety to protect man and machine

- High operational reliability and availability of technical systems and communication equipment

- Immediate notification of insulation deterioration instead of random testing

- Cost-intensive downtimes and system standstills are avoided

- No unplanned or expensive maintenance work

- Clear reduction in maintenance and operating costs

What is your benefit?

Thanks to preventive fire protection through permanent residual current monitoring or insulation monitoring, preventive safety to protect people and machines from hazards caused by electrical current is ensured on the one hand, while high operational safety and availability of the technical systems is guaranteed by immediately localizing and eliminating insulation faults on the other. As a result, maintenance and operating costs can be significantly reduced. The risk of failure due to unexpected activation of existing protective devices is reduced to a minimum.

Due to the constant monitoring of the residual current in electrical installations of systems and devices, insulation deterioration is immediately visible and reported.

This also fulfills an important prerequisite for fire protection work by the fire department.

What is your advantage?

- Precautionary safety to protect man and machine; potential fire hazards are detected as soon as they arise thanks to high residual currents.

- Significant reduction in maintenance and operating costs. Unplanned or expensive maintenance work is not necessary.

- High operational reliability and availability of technical systems and communication equipment. Cost-intensive downtimes and system standstills are avoided.

- Immediate notification of insulation deterioration with constant monitoring.