Insulation monitoring

Insulation monitoring devices (also known as insulation monitors) permanently monitor the insulation resistance of IT systems (unearthed systems) and emit a message if a response value is not reached.

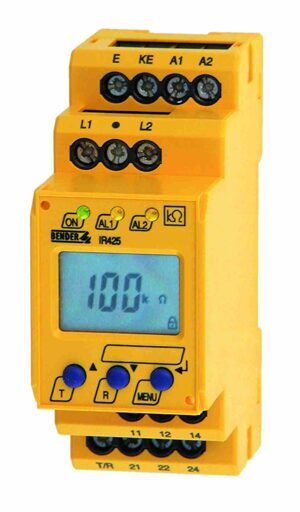

ISOMETER - Insulation monitoring devices

ISOSCAN - Equipment for insulation fault location EDS

Take advantage of our 1A service:

- Planning and conceptual design

- Device selection and project planning

- Commissioning and testing

- Operation and maintenance

- Expansion and modernization

- Optimized maintenance of systems and machines

- Localization of faulty current paths

- Remote diagnostics via Internet/Ethernet

- Monitor areas at risk of fire

- Avoid cost-intensive system downtimes

- Providing technological support for investment protection

- Protection of high-availability systems

- Permanently monitor systems even when they are at a standstill

- Increased accident safety in small and medium-sized systems

Type W device version with increased shock and vibration resistance

- AC, DC or AC/DC main circuits

- AC/DC main circuits with directly connected direct current components such as power converters, Inverters, controlled drives

- UPS systems, Battery networks

- Heaters with phase angle control systems

- Systems with switching power supplies

- IT systems with high leakage capacitances

Insulation monitoring in systems with a low insulation level

Application example: Induction furnaces are devices and systems with which metals can be heated and melted by inductive heating. The energy is transferred by means of a current-carrying coil. This heating is made possible by the induction of an eddy current in a metallic conductor, the workpiece to be heated.

This generally results in a very low insulation resistance in the range of several ohms (Ω) to several kilo ohms (kΩ). For this reason, reliable insulation monitoring is very important. It must be able to measure low insulation values at relatively high operating voltages and raise an alarm to prevent dangerous operating situations.