Since December 2017, the world's steepest funicular has been traveling from Schwyz directly to the idyllic mountain village of Stoos. With this mammoth project, the operators of Bergbahnen Stoos, chairlifts and the new funicular are setting new standards in rail transport.

- World record ascent: The funicular overcomes a maximum gradient of 110% (47 degrees). No other funicular in the world is steeper.

- High capacity: Up to 1,500 passengers can be transported in each direction in one hour. That's 500 passengers more than the old funicular.

- Short journey time: The journey time is just 4 to 7 minutes, significantly less than before. In addition, the mountain station is located in the middle of the village, right next to the skiing and hiking area, which significantly increases convenience.

- Convenient ascent: the cable car climbs 744 meters in altitude from Schwyz to Stoos. Thanks to the automatic level compensation of the cabins, you are always on a level surface - particularly comfortable and wheelchair-accessible.

- Long distance: The distance from the valley station to the mountain station is 1,740 meters.

- High transport capacity: One cabin holds 34 people. With four cabins per car, this results in a transport capacity of 136 passengers per trip.

- Long-term planning: The planning and implementation period lasted 14 years, during which eleven votes were successfully won.

- Sustainable heating: Since December 2022, the entire mountain station, the Stoos Shop and the Stoos Lodge have been heated using waste heat from the funicular's engine room. In addition, the heating water in the Stoos Lodge is heated using the recuperative braking energy of the funicular.

A mammoth project for the Stoos mountain railroads

What was the challenge to be solved?

On each journey, the funicular feeds electrical energy back into the grid after crossing the carriages in the second half of the journey Of the journey, the funicular feeds electrical energy back into the grid. This large amount of energy should be utilized. It was therefore decided to initiate a project to heat water as part of the new hotel construction at the mountain station.

- Efficient use of energy: The electrical energy fed back into the system was to be used sensibly in order to reduce dependence on external energy sources.

- Sustainability: An environmentally friendly and sustainable solution for water heating was to be found in connection with the construction of the new hotel at the mountain station.

- Integrated energy supply: The use of recuperative braking energy from the funicular to heat the Stoos Lodge and for hot water preparation is an example of innovative and sustainable energy use.

What were the specific requirements?

The aim was to use the recuperated energy efficiently. Two large, customized hot water boilers were built for this purpose. Each of these steel tanks was equipped with eleven heating elements, each with an output of 8*31.6 kW and 3*63.2 kW. This allowed the energy to be used in the short term to heat up the heating elements with 442.4 kW per boiler.

- Custom-made hot water boilers: Two large steel tanks were specially manufactured for the project to meet the requirements.

- Powerful heating elements: Each boiler was fitted with eleven heating elements with an output of 8*31.6 kW and 3*63.2 kW, enabling short-term heating with a total of 442.4 kW per boiler.

- Measurement and control technology: Optec's measurement power was used to control and optimize the heating elements. UMG measuring devices and a type 153 enline peak load optimization computer took over the controlled firing of the heating elements.

Our approach to a successful solution

In order to use the recuperated energy efficiently, we have chosen a coordinated approach with state-of-the-art technology.

Enline controller type 153 receives the relevant measurement data from the UMG measurement devices. Based on this data, the controller switches on the heating elements of the hot water boilers one after the other to heat up the hot water tank. This is done in conjunction with the cable car journeys so that the recuperated energy is used every time the cable car runs.

This coordinated system ensures optimum use of the energy generated when the cable car brakes and contributes to a sustainable and efficient energy supply.

What have we actually implemented?

Hot water storage and use

The hot water produced is used as a hot water storage tank for the operation of the station and the entire Stoos Lodge hotel complex. This ensures a reliable and efficient supply of hot water.

In addition, critical consumers in the hotel kitchen and wellness area were controlled and optimized with a second Enline controller type 153. This system enabled us to implement a peak load management system from Optec, which monitors and regulates energy consumption.

- Efficient use of hot water: The entire facility benefits from an optimized hot water supply.

- Additional energy gains: Critical consumers in the hotel are efficiently controlled, leading to further energy savings.

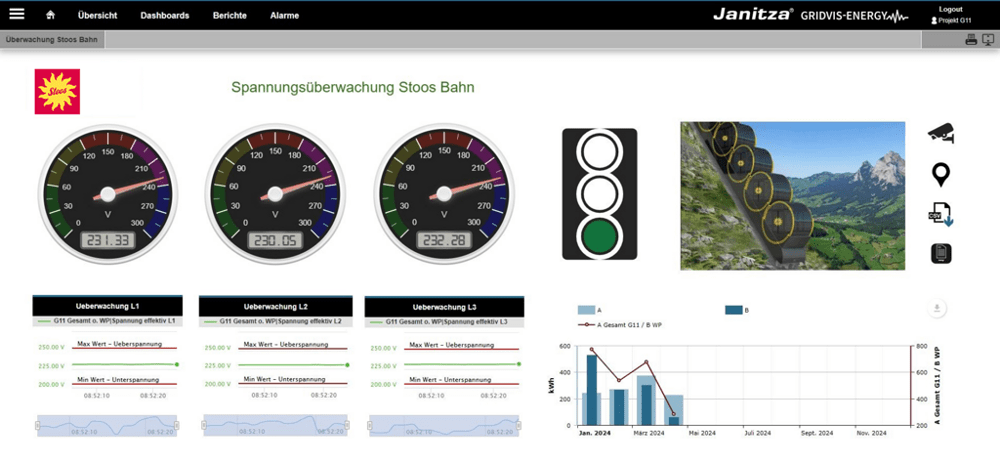

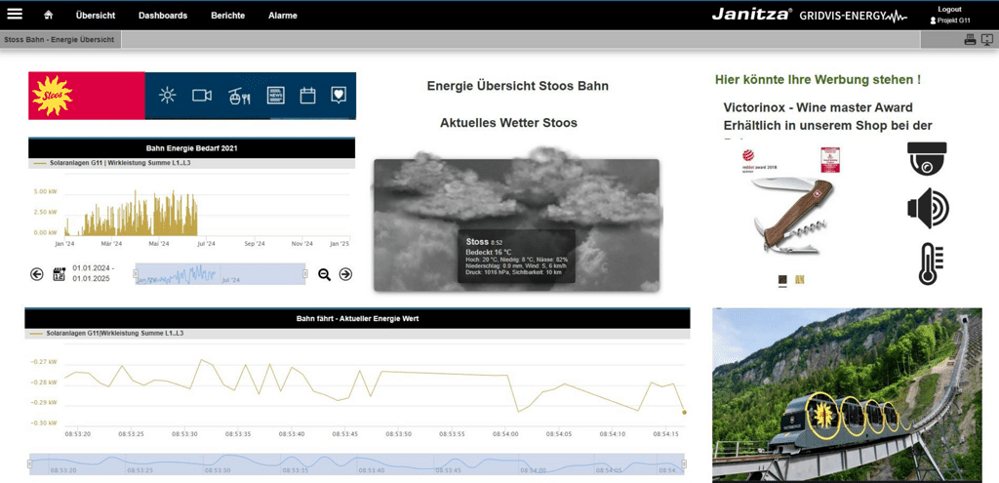

You can see our proposal for the implementation of the dashboard here.

Which products did we use and for what purpose?

- Enline Controller Type 153

- IP modules

- UMG 604

We use the UMG 604 devices from Janitza for the mountain railway system. They are networked via Ethernet and enable central data retrieval and monitoring on the Stoos. The Enline controller type 153 coordinates the control and optimization of the heating elements in the hot water boilers and the critical consumers in the hotel to ensure efficient energy management.

The image is our proposal for the implementation of the dashboard.

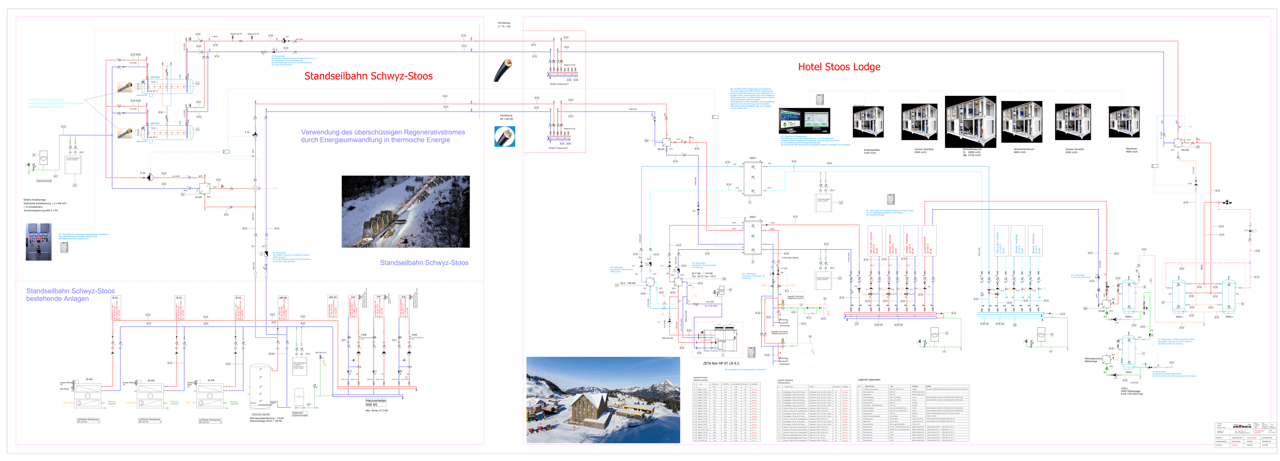

Scheme